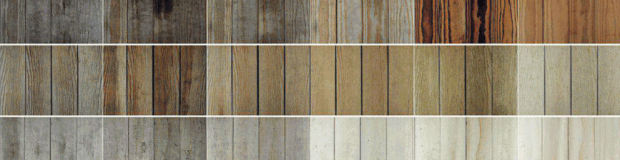

Wood has distinctive characteristics as evident in its various textures and many different shades of colors, as it is one of the most beloved architectural materials from ancient time universally. Its light weight and durability enables for structural applications. They can be a sustainable material, especially if you stick with lumbers from certified yard (i.e. The Forest Stewardship Council). However, its vulnerability against harmful UV rays and moisture remind us of utmost care for certain applications.

The treatments of wood vary significantly depending on its applications and the micro climate. Paradoxically, it is possible to utilize untreated wood as exterior finish, if used properly to prevent from direct sunlight and contact to moisture, (in addition, certain heartwood species such as cedar, redwood, Brazilian hardwood are more resistant to decay due to higher tannin content); otherwise, the process of decomposition within wood substance is induced by harmful UV (in the range of the short wave length in sunlight). This is commonly known as yellowing or browning. If this natural process further proceeds, the regions near the surface start decomposing, which causes so-called “graying” or erosion of wood, although “graying” effect is sometimes desirable aesthetically and this natural patina is a weathering process with a high UV protection. To prevent this, there are various types of coatings available; namely paints, scumbles and varnishes.

The pigmentation and transparency of the coating are closely linked to the degree of protection from the harmful UV rays. With pigmented coating (i.e. paints), the retention of the color can be achieved for a long period of time. Scumbles, on the other hand, become darker as they age and require reapplication of opaque coatings to revitalize the original color. Moreover, the appearance can be varied depending upon the surfacing prior to the application of coatings. With surfaces that are planed, the grain of wood is covered and no longer visible from a greater distance, once a coating is applied. With rough-sawn wood, coating with opaque lacquers does not prevent the wood grain from being invisible from a greater distance. Transparent coatings are gaining popularity, as they retain the grain appearance from a greater distance. In this case, only scumbles with transparent iron oxide pigments (commonly in different shades of brown, red and yellow) absorb enough light in short wave length to prevent the decomposition process.

It should also be noted that paint film in the pigmented coating can prevent rain or moisture from intruding, thus it prevents cracks within wood from forming, especially important for dimensionally stable products such as windows, doors or plywood. This is due to the wood cell structure, which allows expansion and contraction parallel to grain. However, for the applications where ample degree of expansion and contraction is allowed, moisture protection of wood is relatively less important, thus thin scumbles are commonly used for wood siding for facades.

The important points on moisture protection of wood are the thickness of coating, the type of bonding agent, and color of coating. If further moisture protection is desired, you can use a thicker coating with solvent-base alkyd resins (instead of water soluble bonding agents) and choose lighter shades of color. This approach enables the moisture content in wood from reaching critical levels; however, we have to take consideration of the fact that weathering can cause cracks in coating in time and allow moisture to build up within. Therefore, it is only effective for a limited time period and must be maintained properly.